Products

Our Innovations

Industry Focused Products!

Optimized & Industry-ready Solutions

For All Your Complicated Needs

When it comes to addressing complicated needs in the hydraulic press industry, it’s essential to have a thorough understanding of the specific requirements and challenges you’re facing. Hydraulic presses are versatile machines used in various industries, including manufacturing, automotive, aerospace, and more. Here are some considerations and tips for handling complicated needs with hydraulic presses:

Identify Your Needs: Start by clearly defining your specific requirements. What is the desired end result? Are there any unique challenges or constraints?

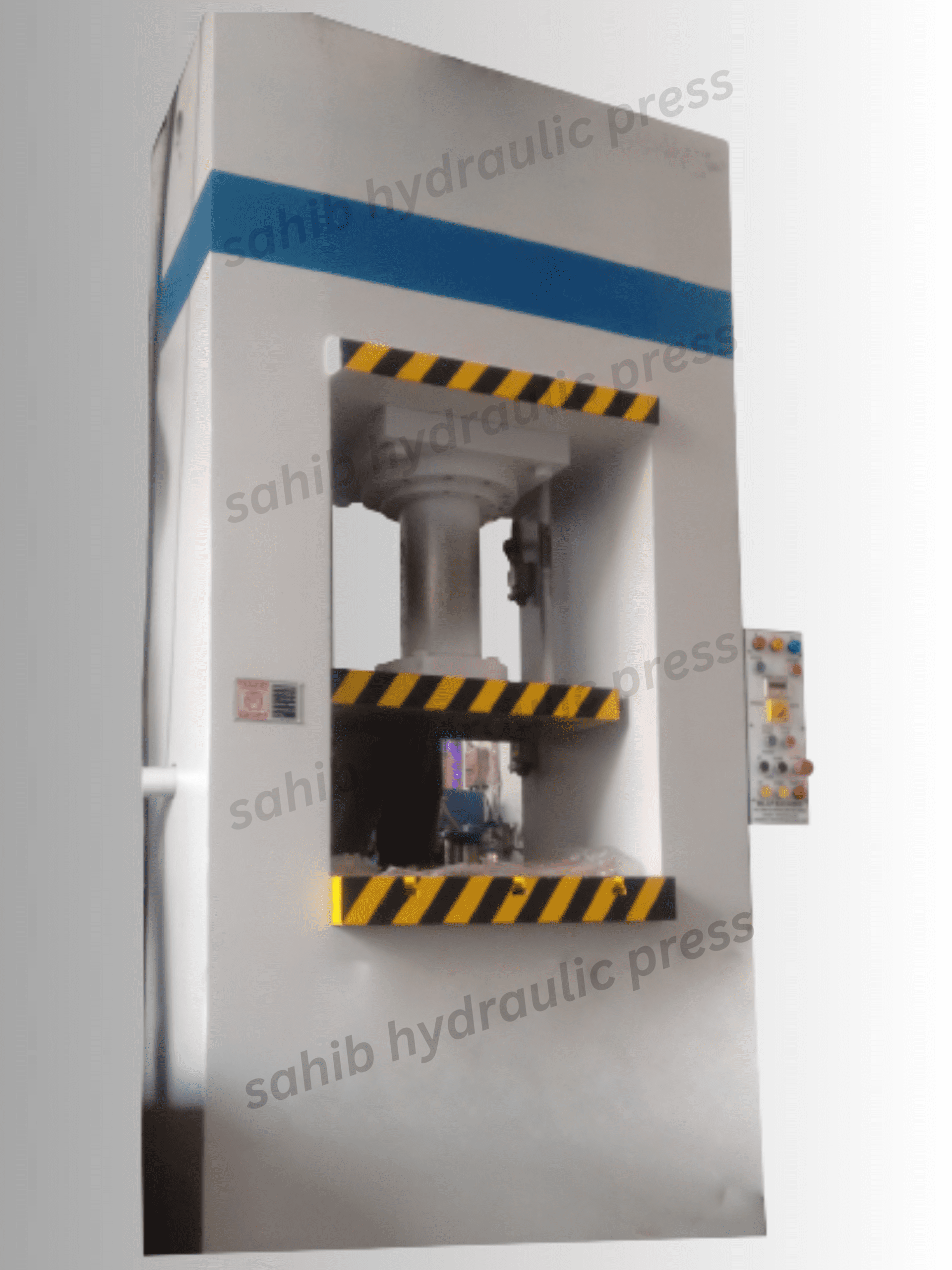

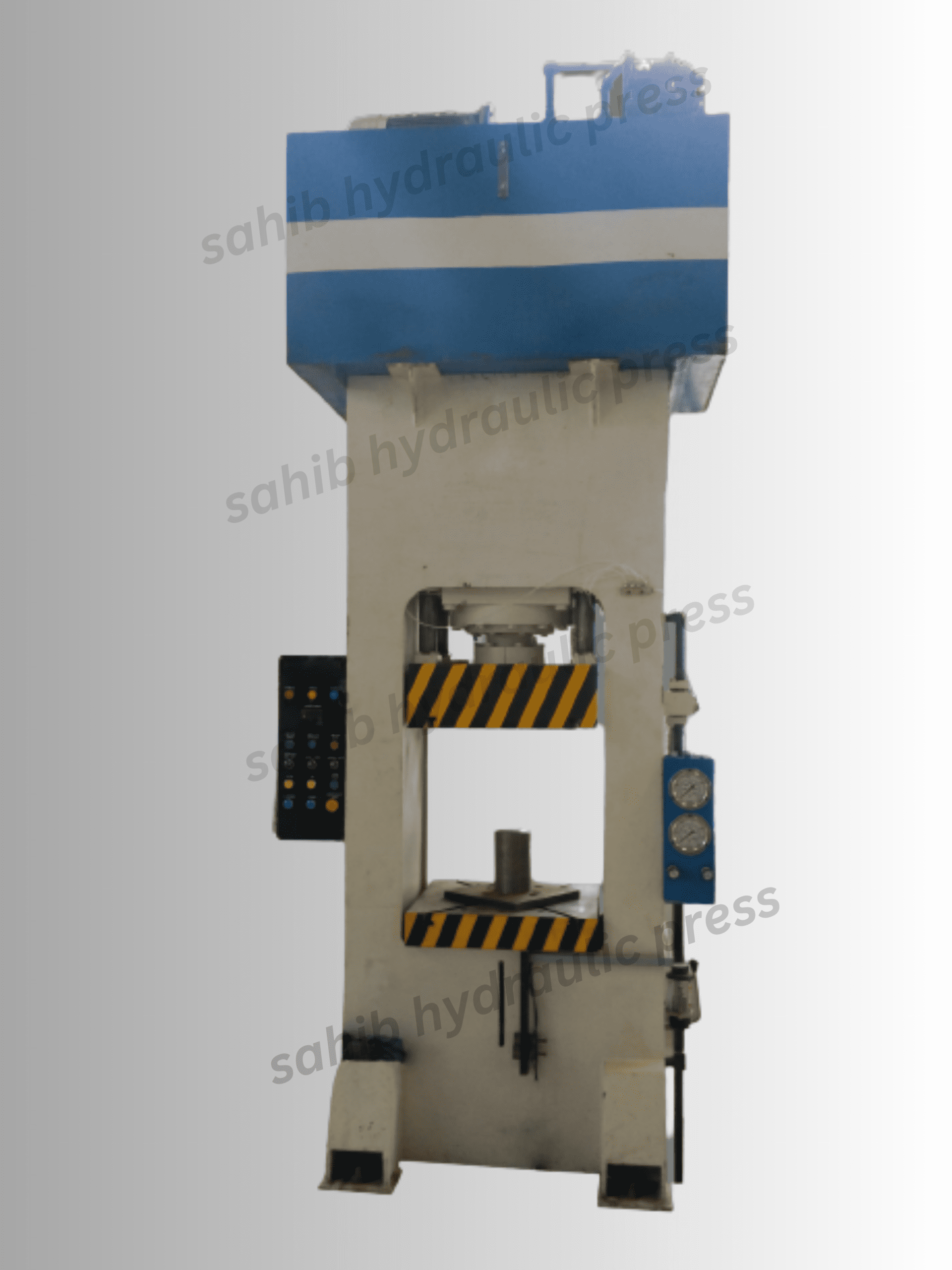

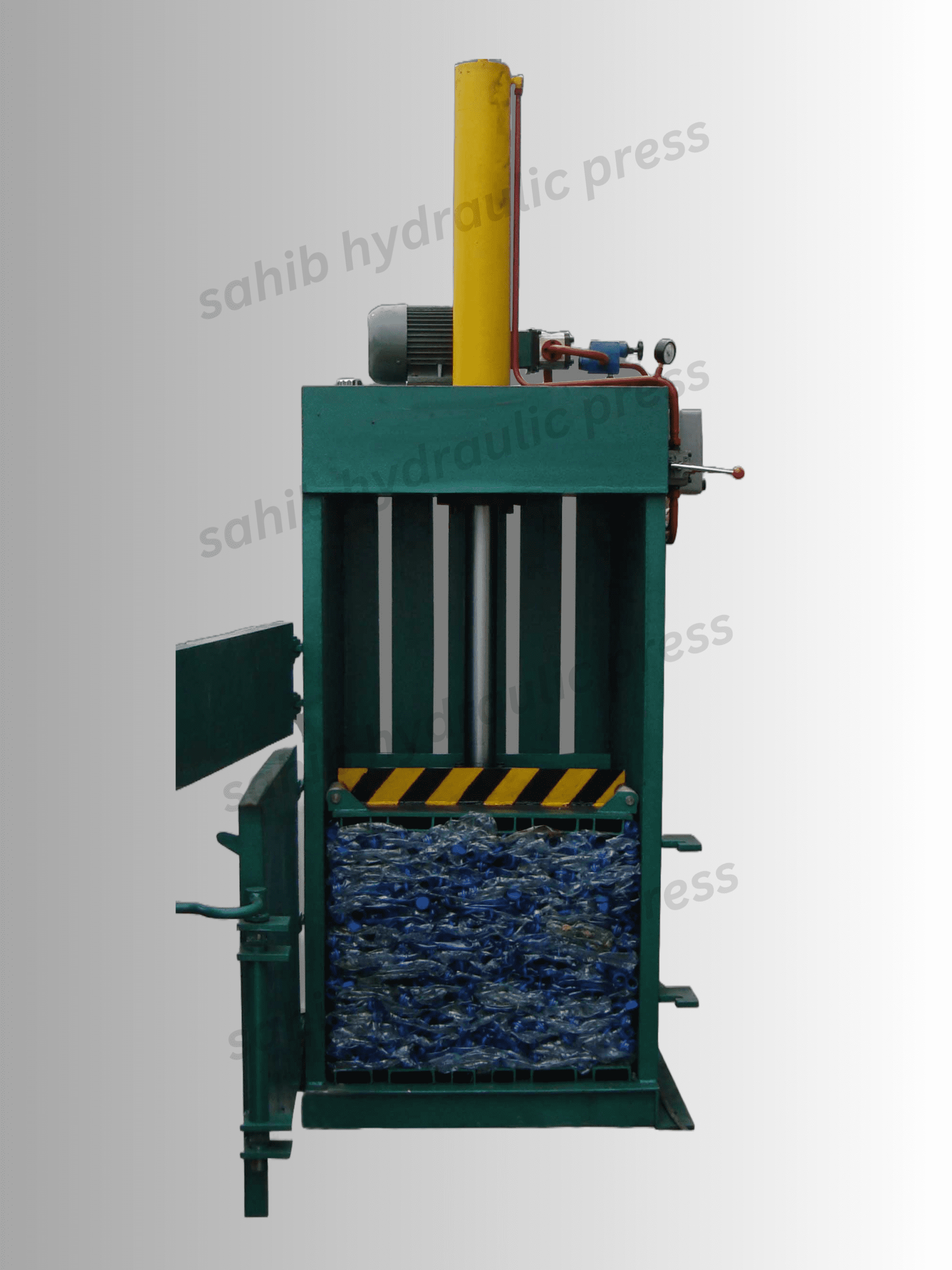

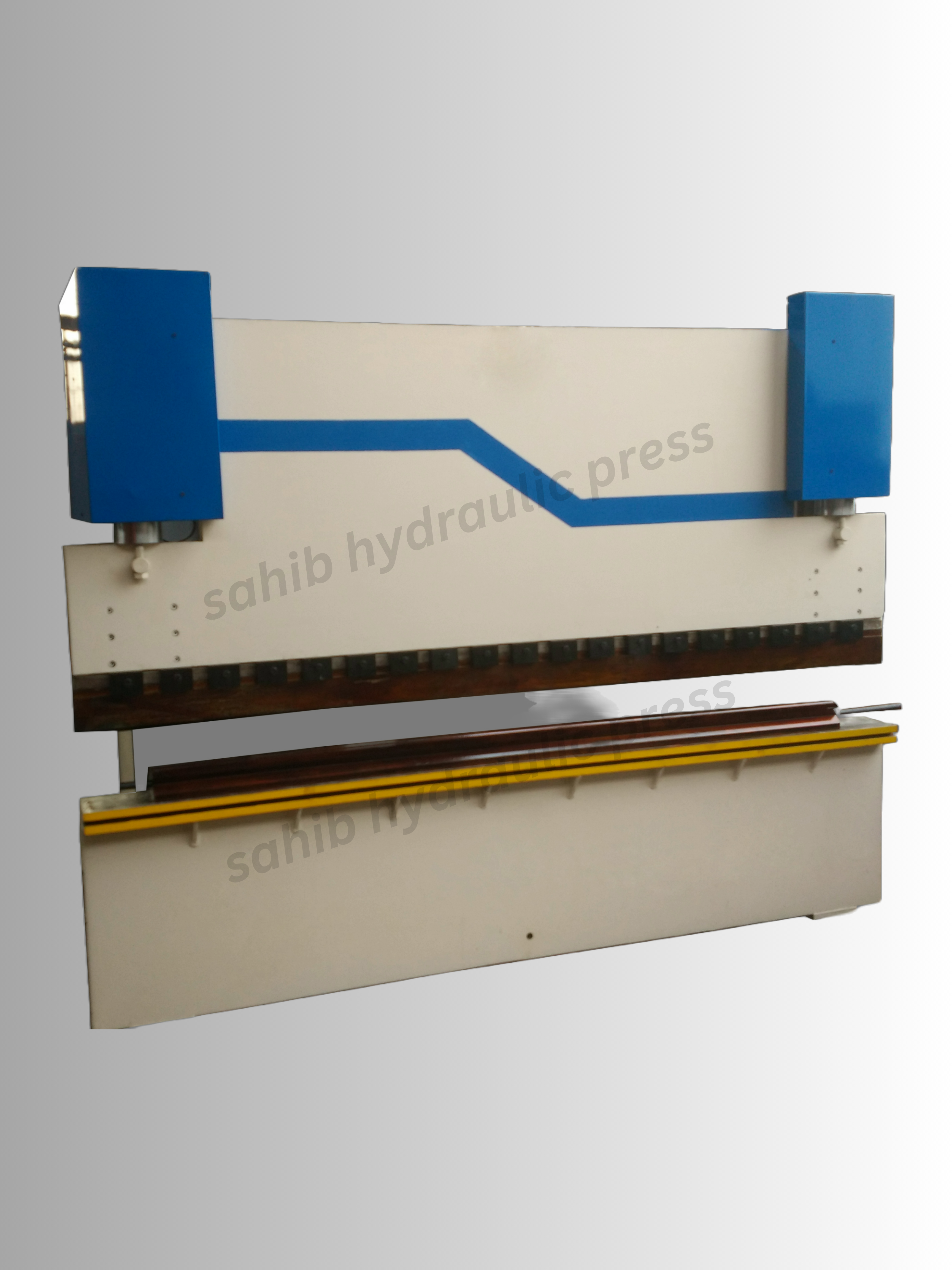

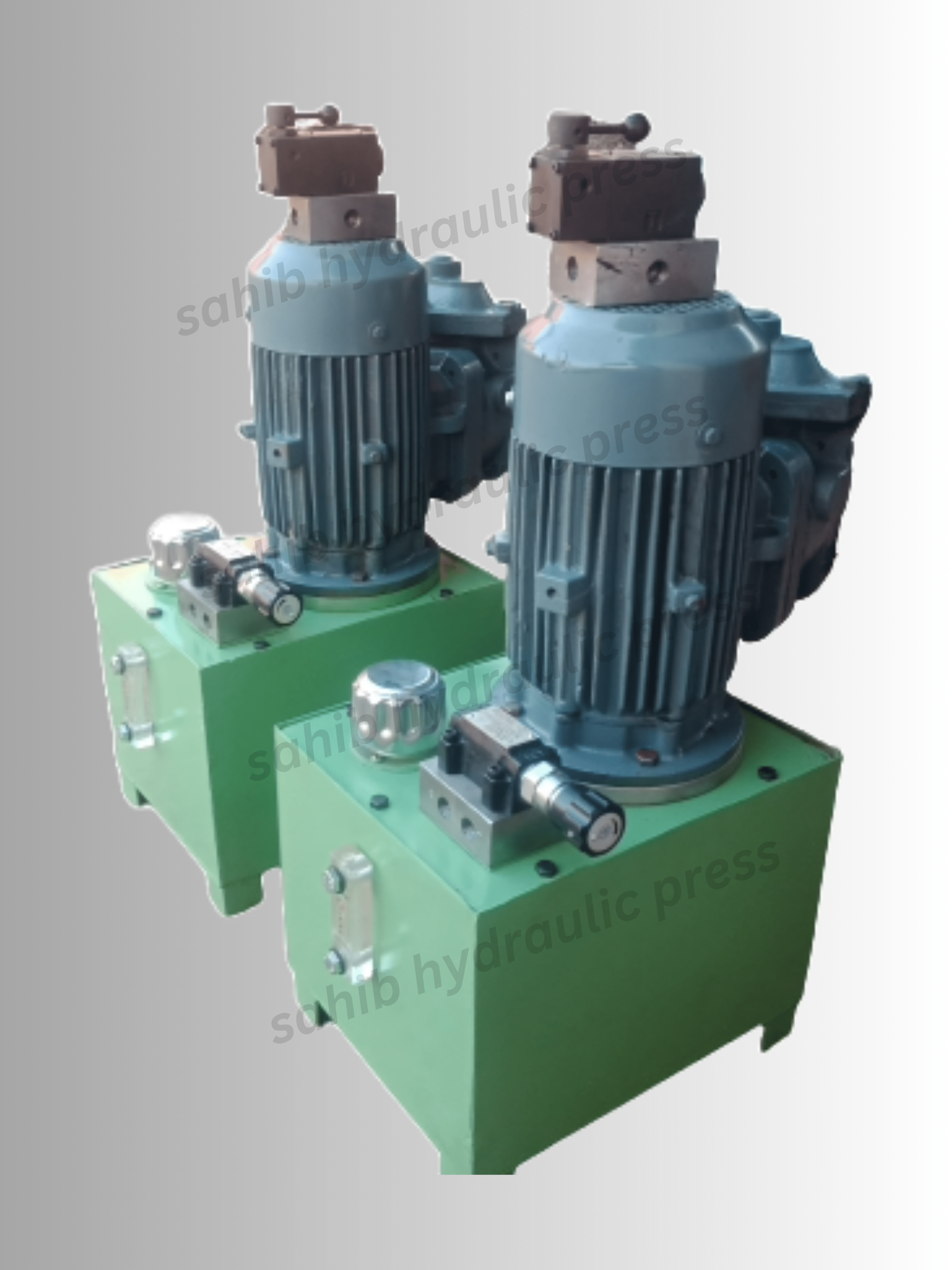

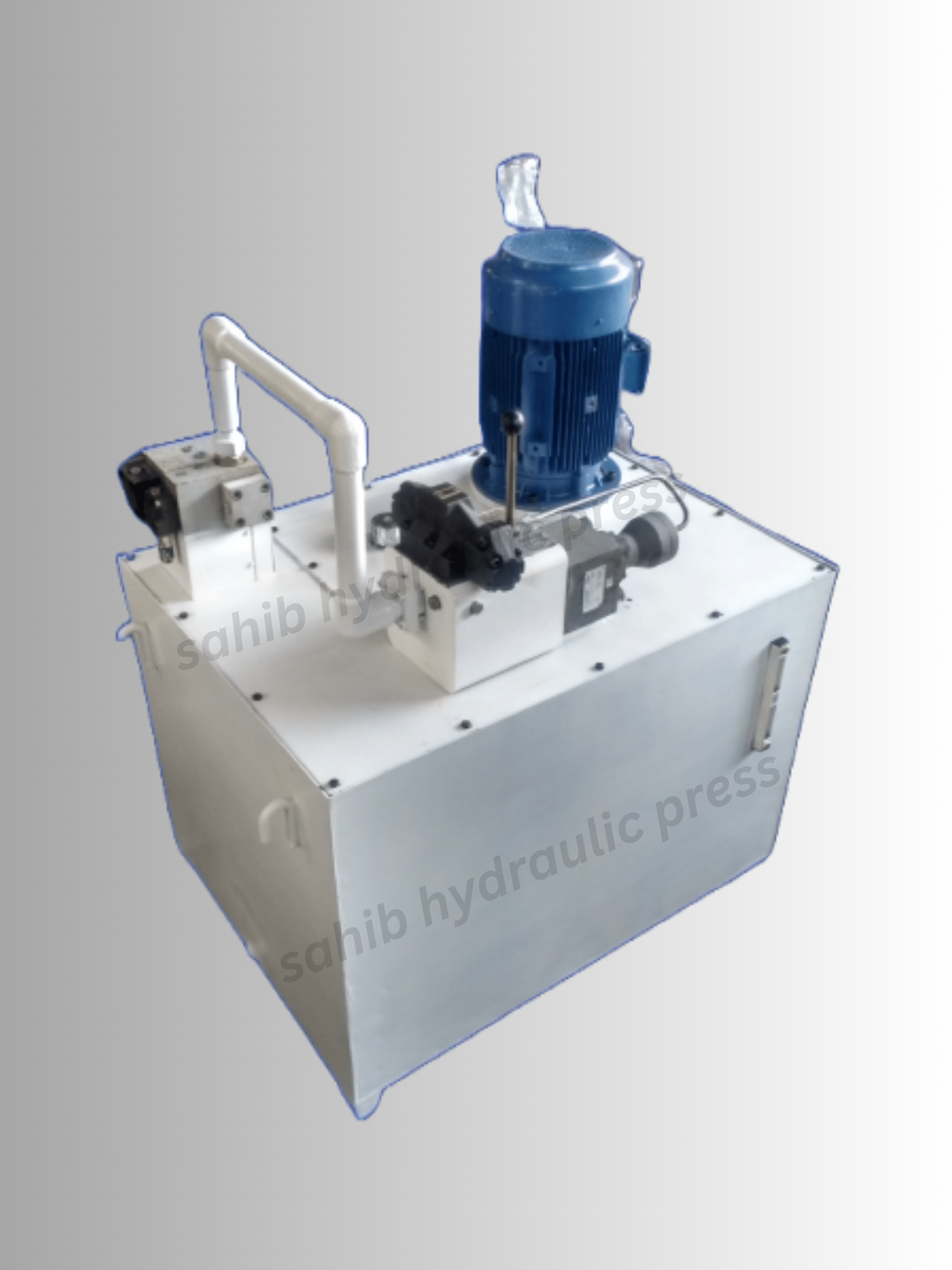

Select the Right Hydraulic Press: There are various types of hydraulic presses available, such as C-frame, H-frame, four-column, and more. Choose a press that suits your industry and can provide the necessary force and precision.

Capacity and Force: Ensure that the press you choose has the required capacity and force to handle your tasks. Consider factors like tonnage, stroke length, and speed.

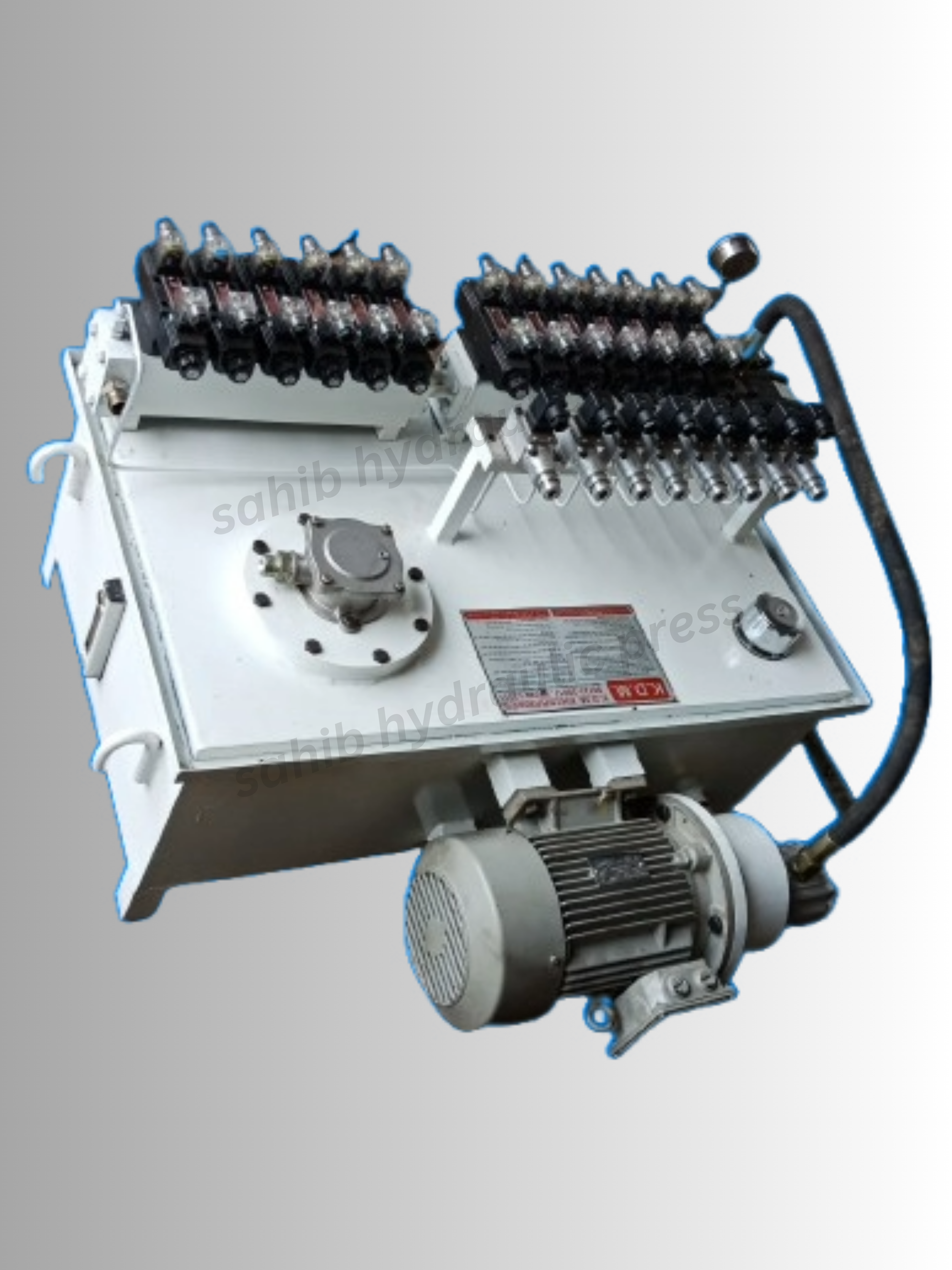

Control Systems: Modern hydraulic presses often come with advanced control systems that allow for precise control of force, speed, and position. Choose a press with a control system that meets your needs.

Tooling and Accessories: The choice of tooling and accessories is crucial. Different tasks may require various types of dies, punches, and other tooling components. Ensure that you have the right tooling for your industry.

Safety: Safety should always be a top priority when working with hydraulic presses. Make sure your press is equipped with safety features such as emergency stops, safety guards, and interlocks.

Maintenance and Inspection: Regular maintenance and inspection of your hydraulic press are essential for ensuring its long-term reliability and performance. Follow the manufacturer’s maintenance guidelines.

Operator Training: Ensure that operators are properly trained to use the hydraulic press safely and efficiently. They should be familiar with the machine’s controls, safety procedures, and troubleshooting.

Process Optimization: Continuously analyze your hydraulic press processes to identify areas for improvement. This could involve optimizing cycle times, reducing material waste, or enhancing product quality.

Consult Experts: If your hydraulic press needs are particularly complex or specialized, consider consulting with experts or engineers who have experience in your industry.

Customization: In some cases, you may need a customized hydraulic press designed specifically for your industry. Working with a manufacturer that offers customization options can be beneficial.

Testing and Quality Control: Implement thorough testing and quality control procedures to ensure that your hydraulic press meets your performance and product quality standards.